Dynamic models and manipulation for soft manipulators

dynamic models for soft continuum manipulators

- integral lagrangian formulation [1]

- derive a dynamic model for a variable length multi-section continuum arm with N sections

- modal kinematics -> integral Lagrangian for single section -> piece-wise formulation

- integral Lagrangian formulation

- Assuming continuum sections are made up of infinitesimally thin slices,

- first the kinetic energy (KE) and potential energy (PE) are derived for a thin slice

- then the total energies are found by integrating along the length of the arm

- The Lagrangian is then utilized to derive the continuum arm equations of motion.

- limitation

- closed-form expressions

- complicated as the number of segments increases

- unpractical for real-time applications

- numerical instabilities

- derive a dynamic model for a variable length multi-section continuum arm with N sections

- lumped mass assumption [2]

- acceleration-level control in joint space based on a dynamic model of a constant curvature continuum manipulator with multiple sections.

- spatial dynamic model (describe the motion of a physical system in three-dimensional space) → one mass point per section.

- feedback linearization (transforming the nonlinear system into a linear system by using feedback)

- decouple the nonlinear couplings between the actuators such that fast trajectories can be tracked

- acceleration-level control in joint space based on a dynamic model of a constant curvature continuum manipulator with multiple sections.

- curvature space methods+inverse kinematic approaches [3]

- use kinematic models for controlling the spatial location and trajectory of the manipulator's end effector

- solve the three chamber lengths from the given position → control pressure to make the arm to follow trajectories

- use kinematic models for controlling the spatial location and trajectory of the manipulator's end effector

- RNN [4]

- reduce the dynamic model of a soft robot to first-order dynamical equation owing to their high damping and low inertial properties, as typically observed in nature, with minimal loss in accuracy

- can be powerful for developing closed-loop task-space dynamic controllers for soft robots by simplifying the planning and sensory feedback process

- use a nonlinear autoregressive exogenous (NARX) model, a kind of recurrent neural network

- receives only zeroth-order feedback for the first-order model

- receives the appended first-order feedback for the second-order model

- approximation with augmented rigid body model

- piecewise constant curvature (PCC) model by adding a rigid link model and mass points

- task space control

- quasistatic assumption

- tip-follower actuation using local kinematics

- by deriving locally approximated Jacobian from a model or learned

- no gravity / inertia

- no quick movements and skillful force application, as the actuation steps must be kept small to prevent the robot from oscillating.

- tip-follower actuation using local kinematics

- dynamic approaches

- dynamic model

- Material model-based closed-loop trajectory control [5]

- The continuum manipulator is treated as a composite material, and a modified nonlinear Kelvin-Voigt material model is utilized to embody the visco-hyperelastic dynamics of soft silicone.

- The Lagrangian approach is applied to derive the equation of motion of the manipulator

- Position regulation [6]

- use integral action to model the uncertain kinematics of the manipulators

- estimate the static mapping of a single coordinate (in-plane tip rotation) in Cartesian space is extended to the 3D case by considering the out-of-plane tip rotation

- employ a port-Hamiltonian formulation and a passivity-based approach to compensate the effect of unknown external forces acting on the tip of the manipulation

- model and control in terms of energy exchange by representing the dynamics using a Hamiltonian function

- describes the system's energy

- how the system's energy changes over time

- model and control in terms of energy exchange by representing the dynamics using a Hamiltonian function

- use integral action to model the uncertain kinematics of the manipulators

- sliding mode controller [7]

- Slotine-Li Adaptive Control Scheme

- an adaptive control method that enables the controller to estimate the dynamic coefficients (mass, inertia, and friction properties) of the robot online.

- difficult to measure accurately

- vary with time due to changes in the robot's configuration or environment

- uses feedback from the robot's joint positions and velocities to estimate these dynamic coefficients

- adjust the controller in real-time accordingly

- an adaptive control method that enables the controller to estimate the dynamic coefficients (mass, inertia, and friction properties) of the robot online.

- Adaptive Approach for Estimating Unknown Disturbance Bounds:

- monitor the output of the controller and adjusting the bounds of the disturbances based on how much the output deviates from the desired behavior

- Terminal Sliding Mode Control Strategy

- sliding mode control is a type of nonlinear control strategy that aims to drive the system to a desired state by creating a sliding surface that the system's state trajectory must follow

- terminal sliding mode control

- ensure that the sliding surface is reached in a finite amount of time → reduce the time required to achieve the desired state

- increase the convergence rate of the tracking error

- Slotine-Li Adaptive Control Scheme

- Material model-based closed-loop trajectory control [5]

- dynamic model

- quasistatic assumption

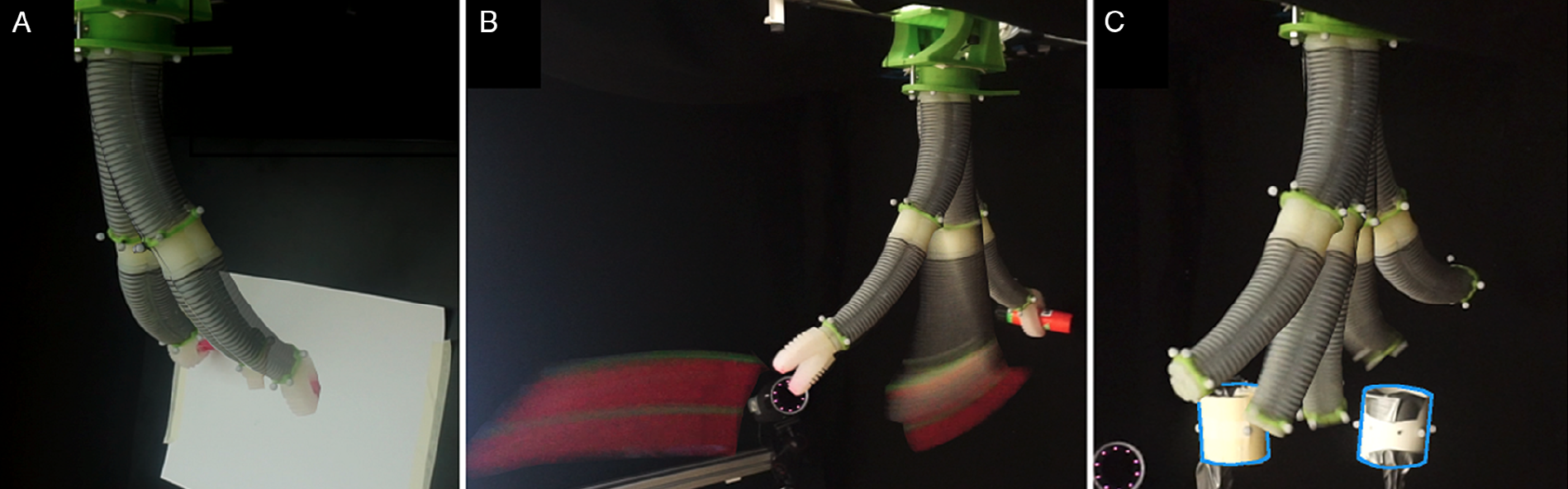

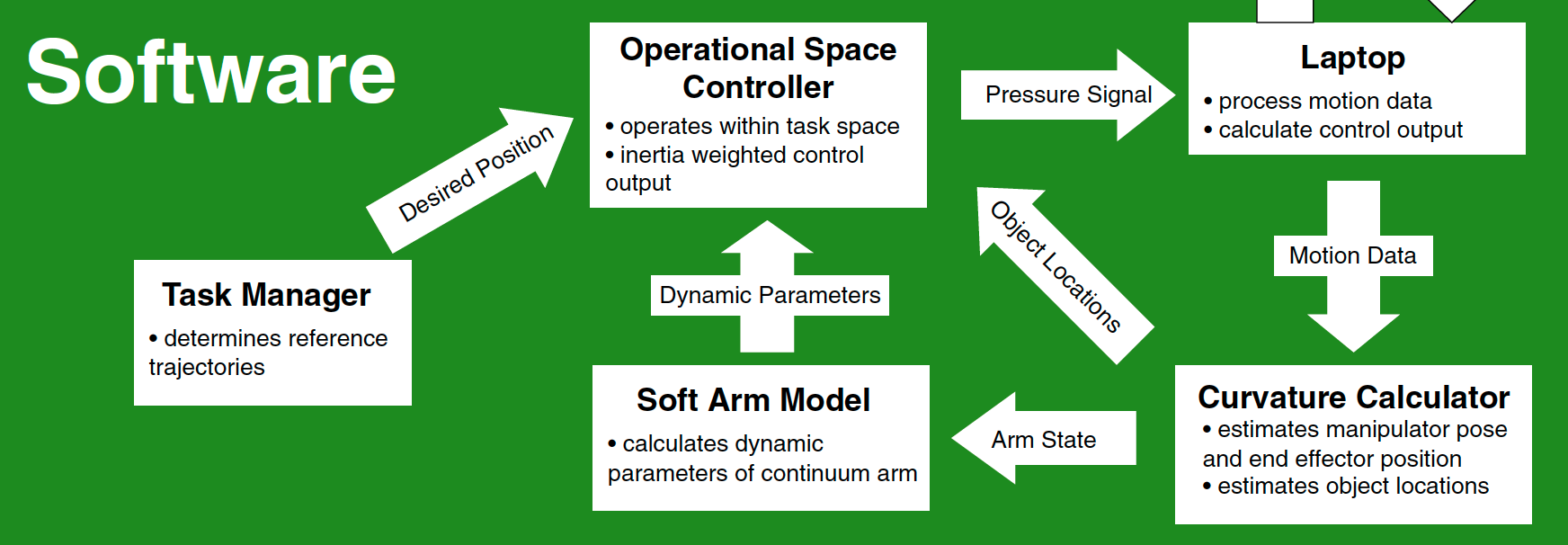

Dynamic manipulation of soft manipulators[8]

- Goal: build a dynamic approach to control and modeling that allows soft robots to move faster and handle external forces more efficiently.

- Motivation:

- The maximum velocity that can be achieved through dynamic control is dependent on

- speed of the motion tracking system, the accuracy of the PCC-based model, and the time required for computation.

- On the other hand, quasi-static controllers are inherently slower and cannot achieve high velocities.

- The maximum velocity that can be achieved through dynamic control is dependent on

Methods and results

- Combine dynamic modeling, dynamic task space control, and system identification methods to experimentally validate the integration of these elements on a real-world soft manipulator.

- Improve the accuracy of the dynamic model of the multisegment continuum robot by adding experimentally determined error correction terms to actuation and stiffness matrices.

- Experiments (dynamically control motions in 3D task space)

- Pick-and-place: the manipulator moves at a higher velocity than possible with quasistatic control, and handles a load while moving toward the drop-off spot.

- Throwing objects: perform velocity control to stabilize after reaching a high speed with the improved dynamic model

- Drawing a straight line: use the dynamic model to apply tip forces and follow given trajectories

—

—

Limitations

- workspace

- increase workspace by replacing the joint at the base

- online programming of the actuation behavior

- PCC assumptions

- Cosserat rod model instead -> hard to model for control with the nonconstant curvature approaches

- improved kinematic models to improve estimation of nonlinear actuation and stiffness behavior

- improced accuracy will give opportunityies for model predictive control

- experimentally determined error correction terms for dynamic model -> system identification of every manipulator

- analyze errorr sources -> anisotropic stiffness, wall thickness, manufacturing quality

- couple with FEM for better state estimation

- heavily rely on motion capture system

- cheaper options: embedded bend sensors, inertial measurement units for state estimation

[1] Godage, Isuru S., et al. "Dynamics for variable length multisection continuum arms." The International Journal of Robotics Research 35.6 (2016): 695-722.

[2] Falkenhahn, Valentin, et al. "Model-based feedforward position control of constant curvature continuum robots using feedback linearization." 2015 IEEE International Conference on Robotics and Automation (ICRA). IEEE, 2015.

[3] Gong, Zheyuan, et al. "A soft manipulator for efficient delicate grasping in shallow water: Modeling, control, and real-world experiments." The International Journal of Robotics Research 40.1 (2021): 449-469.

[4] George Thuruthel, Thomas, Federico Renda, and Fumiya Iida. "First-order dynamic modeling and control of soft robots." Frontiers in Robotics and AI 7 (2020): 95.

[5] Mustaza, Seri Mastura, et al. "Dynamic modeling of fiber-reinforced soft manipulator: A visco-hyperelastic material-based continuum mechanics approach." Soft robotics 6.3 (2019): 305-317.

[6] Franco, Enrico, et al. "Position regulation in Cartesian space of a class of inextensible soft continuum manipulators with pneumatic actuation." Mechatronics 76 (2021): 102573.

[7] Kazemipour, Amirhossein, et al. "Adaptive dynamic sliding mode control of soft continuum manipulators." 2022 International Conference on Robotics and Automation (ICRA). IEEE, 2022.

[8] Fischer, Oliver, et al. "Dynamic Task Space Control Enables Soft Manipulators to Perform Real‐World Tasks." Advanced Intelligent Systems 5.1 (2023): 2200024.